Release time:2017-05-22

Number of clicks:2728

Product inquiry

Continuous casting process is an advanced continuous molten steel casting technology. Tundish is used to store molten steel in continuous casting system according to the process requirements, and tundish scale is a key detection link in the process of molten steel continuous casting. The opening of large ladle nozzle is adjusted by measuring the weight of molten steel in tundish, and the flow of molten steel into tundish is controlled. Effective control of molten steel level can make the flow of molten steel into the mold stable, reduce the disturbance caused by the change of static pressure of molten steel in tundish to the control of molten steel level, and is beneficial to the floatation of impurities in molten steel. Secondly, according to the requirement of steelmaking process and management, the change of molten steel weight in tundish in continuous casting position is displayed in real time to control the changing time and the weight of molten steel in tundish.

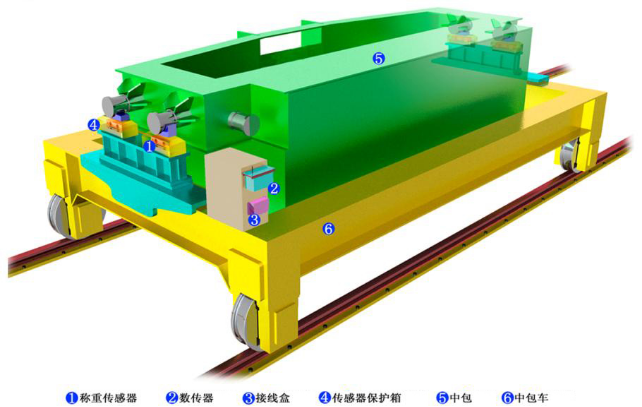

ZBS-1B truck scale for continuous casting tundish is composed of weighing sensor, weighing box assembly, field weighing data transmitter, weighing receiving display and large display.

The measuring range and applicable working environment of ZBS-1B truck mounted scale.

Working environment temperature: sensor - 20 ~ 250 C; weighing data transmitter - 20 ~ 85 C; weighing instrument - 10 ~ 40 C

Working environment humidity: < 95%RH

Working power supply voltage: 22 + 22 - 3 3 VAC 50 + 5Hz

Rated range: 60~200t, indexing: 20~100kg

Weighting accuracy: 0.3-0.5%, technical performance in line with the GB / T7723-2008 "fixed electronic scale" as the accuracy of the general level of accuracy, that is, level 4 standard