Release time:2017-05-22

Number of clicks:2651

Product inquiry

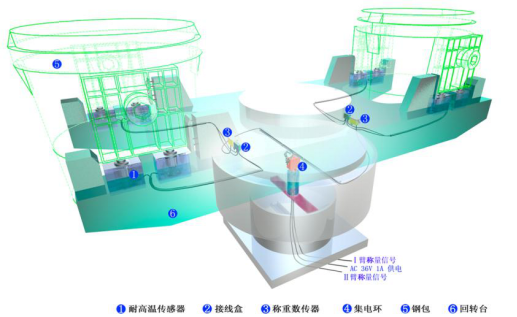

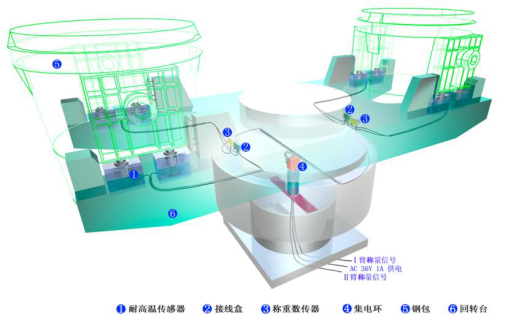

Continuous casting process is an advanced molten steel casting technology imported from foreign countries in recent ten years by our metallurgical enterprises, and the ladle electronic scale (ladle scale) of continuous casting turret is an indispensable on-line real-time monitoring and weighing device for implementing this new process. The ladle scale is mainly used to monitor the flow of molten steel into the tundish to prevent slag from getting involved in the tundish and affecting the quality of billet. However, it is difficult to use the turret reliably under the harsh and special field conditions such as high temperature, impact and rotation. After more than ten years of anatomical analysis of similar products at home and abroad and drawing on more than ten years of successful experience, we have successfully developed a revolving table electronic weighing scale with advanced characteristics, and it is used normally and reliably in several steel companies at home and abroad.

HBS-1C/1B type continuous casting turret ladle scale is composed of weighing sensor, weighing box assembly, field weighing data transmitter, collector ring, weighing receiving display and large display. Among them, the use of on-site weighing data transmitter is our company's first in the domestic counterparts, the advantage is to completely solve the domestic collector ring can not transmit analog mV signal difficult problem. In order to collect data from computer or PLC, the weighing and receiving display has 4-20 mA analog output, and can be equipped with ProfiBus-DP interface as required.

Measuring range and applicable working environment of large scale scale

Working environment temperature: sensor - 20 ~ 250 C; weighing data transmitter - 20 ~ 85 C; weighing other instruments - 10 ~ 65 C

Working environment humidity: < 95%RH

Working power supply voltage: 22 + 22 - 3 3 VAC 50 + 5Hz

Rated range: 60~500t; indexing: 20/50/100/200kg

Weighting accuracy: 0.3-0.5%, technical performance in line with the GB / T7723-2008 "fixed electronic scale" as the accuracy of the general level of accuracy, that is, level 4 standard

Note: 1. Determine the shape and installation size of the large package weighing box according to user's needs. Under normal circumstances, A (> 400), B (> 140), L (> 550) and H (> 360), it can be directly welded and installed, or fixed with bolts.

(2) A turret needs to occupy 6 channels of the collector ring (slip ring), or can also be equipped with our JDH-6 collector ring. Among them, AC36V

1A two, DC24V 20mA 4;

3. Type selection of sensors: CZL-YB-2EH, CZL-YB-7CH and CZL-YB-7CH1;

The model of no disc spring for large scale weighing box of continuous casting turntable is HBS-1B-60 to 300t.

The type of disc spring in the ladle weighing box of continuous casting turntable is HBS-1C-60 to 300t.

(4) The JDH-GD-1 single track large arc slip ring developed by our company can be used when the rotary table is equipped with the simple cover package number of the intermediate column, and the wireless weighing transmission mode can be adopted.