Release time:2017-05-22

Number of clicks:2645

Product inquiry

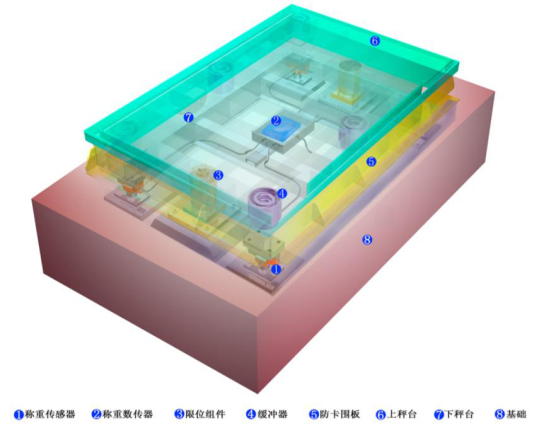

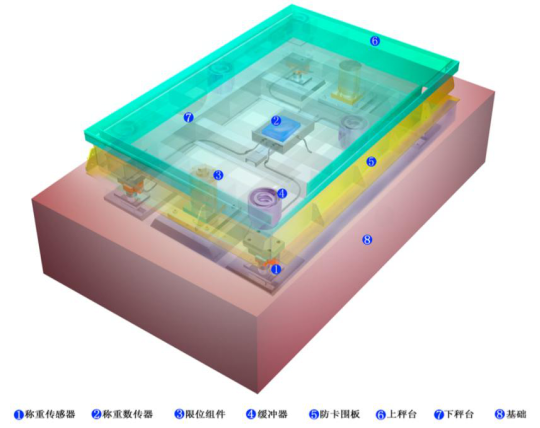

Steel scrap is one of the raw materials for converter or furnace steelmaking. Adding a certain proportion of steel scrap to the steelmaking furnace can increase the output of steel and reduce the temperature of molten steel. Therefore, the quantitative loading of steel scrap is an important link to improve the economic benefits of steelmaking and meet the needs of process. SCS-FGC type scrap steel buffer scale is a special weighing equipment with spring buffer and edge guard gap protection. There are three types of installation: shallow pit, deep pit and ground foundation. In order to prevent the transverse impact between the electric sucker and the material trough (basket), the guide sleeve limit device of the guide column is set. In order to prevent the weighing platform from being moved and moved behind the suction cup, a device for preventing upper warping is installed. As the gap between the scale pits is well protected, the scrap buffer scale can be maintained free of maintenance and can work stably and reliably for a long time.

The scale and applicable working environment of scrap steelyard.

Working environment temperature: sensor - 20 ~ 65 C; data transmitter - 10 ~ 65 C; other instruments - 10 ~ 65 C

Working environment humidity: < 95%RH

Working power supply voltage: 22 + 22 - 3 3 VAC 50 + 5Hz

Rated range: 20~150t; indexing value 10/20/50kg

Weighing accuracy: 0.1-0.3%, technical performance in line with GB/T7723-2008 "fixed electronic scale" the accuracy of the general level of accuracy, that is, 3 or 4 levels of standards.