Release time:2017-05-22

Number of clicks:2596

Product inquiry

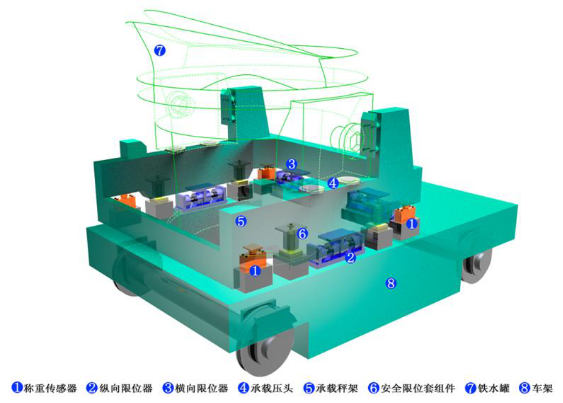

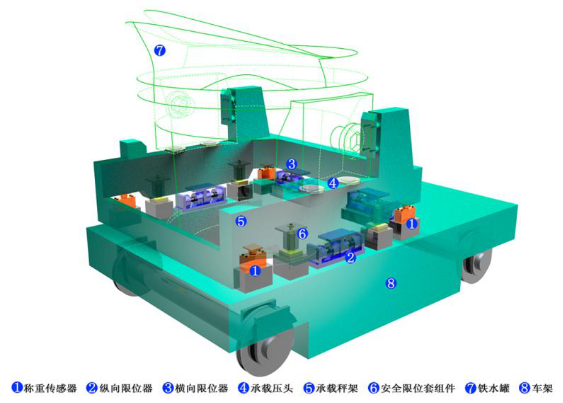

In order to realize high precision (0.1-0.3%) weighing of ladle and molten iron tank, a professional scale frame with anti-collision guide seat and disc spring buffer device and matching horizontal weighing limit device were designed.

Using wireless weighing signal transmission/reception technology, the wireless weighing data transmitter AC36V on the vehicle is supplied by the power supply with protective short-circuit self-recovery safer, which is provided by towing or cable reel, and the inconvenience caused by frequent charging of battery power supply is cancelled.

Because the distance between the general vehicle scale and the receiving instrument is close (< 100M), the weighing and receiving instrument with built-in wireless module can be selected. The frequency point of wireless transceiver module adopts software digital technology. When the spare car is replaced, only the number on the weighing receiving instrument and the setting weighing parameters can be changed. On the wall-mounted instrument cabinet, there are external control zero adjustment, external control peeling and wool/net weight switch buttons, which can conveniently let the large display display iron (steel) water net weight, weighing wiring instrument with automatic zero adjustment function, so that the scale always maintains the correct zero position and long-term accuracy.

Scale and applicable working environment for weighing scales of ladle / ladle car scales:

Working environment temperature: sensor-20 ~ 80'; weighing data transmission / receiving display 0 ~ 85'; weighing display-10 ~ 65'.

Working environment humidity: < 95%RH

Working power supply voltage: 22 + 22 - 3 3 VAC 50 + 5Hz

Rated range: 60~400t; indexing: 20/50/100kg

Weighting accuracy: 0.2-0.3%, technical performance in line with the GB / T7723-2008 "fixed electronic scale" as the accuracy of the general level of accuracy, that is, 4-level standard